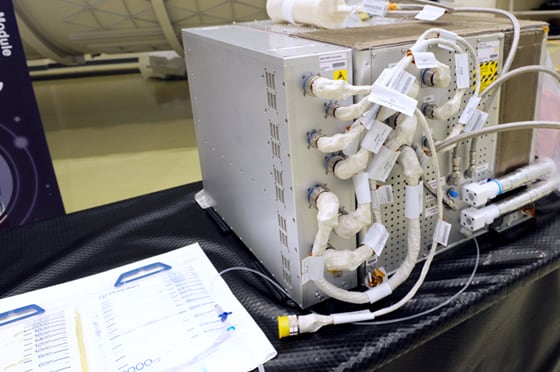

Multipurpose Small Payload Rack -- JEM Water Recovery System

A next-generation water recovery system has taken an important step in establishing readiness for future human exploration missions. A unique water recovery system originated from Japan has being developed. Its technology demonstration system has been operated in the Multipurpose Small Payload Rack (MSPS) onboard “Kibo” of the International Space Station (ISS).

To reduce the amount of water transported from the ground as much as possible, a NASA-provided water recovery system in the ISS is running to recycle water collected from the astronaut’s urine and dehumidification of the cabin air into drinking water.

In order to establish a next-generation water recovery system that is smaller in size, consumes less power, has a higher recovery rate, and is easier to maintain than the water recycle system currently in use on the ISS, JAXA prepares a scale-model of water recovery system for technology demonstration on the Japanese Experiment Module "Kibo".

Water recovery systems, featuring low power consumption, small size, and high efficiency, are considered to be applicable advantageously to future manned space exploration, as well as to drought areas, mountainous areas, and disaster areas where water resources are limited on the ground.

The Significance of Conducting Experiments in Space

Before developing a practical system of next generation water recovery system, a demonstration experiment would be very important to verify each individual function under the microgravity environment, which cannot be simulated on the ground.

On Earth, gravity causes the liquid and gas separation due to buoyancy, but in a microgravity environment, bubbles generated in the liquid do not move toward the surface of the water, and stay in the liquid. Bubbles, once attached to the surface of water treatment section, may stay there indefinitely due to surface tension and interfere with the process.

We will specifically investigate how these tiny bubbles (microbubbles) that stay in the liquid affect water treatment processes, and use findings to develop future water recovery systems.

Working Principle

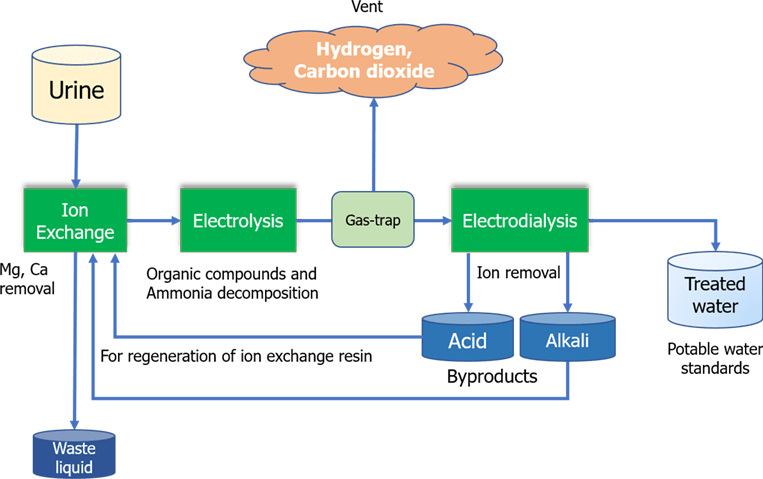

The JEM Water Recovery System(JWRS) recycles urine and artificially synthetic urine into drink-quality water through the following three major treatment processes.

Ion Exchange

Using cation exchange resin, magnesium (Mg) and calcium (Ca) contained in urine are removed. Mg and Ca are also found in hard water and can cause deposits (water scale). Removing Mg and Ca in the first stage prevents clogging of pipes and filters that would occur in subsequent stages.

Electrolysis

Using water electrolysis, organic matter contained in ion exchange treated water is decomposed. Electrolysis conducted at high temperature and high pressure makes it possible to completely decompose even hard-to-decompose organic matter.

Electrodialysis

Any ions left over from the previous process are removed and water suitable for drinking is produced. Samples taken from the produced water are brought back to Earth for laboratory analysis and the like.

The alkaline water and acidic water produced as by-products of electrodialysis is used to regenerate the ion exchange resins. This regeneration of the ion exchange resins is performed automatically, making the system maintenance-free.

Unless specified otherwise, rights to all images belong to ©JAXA