Temperature Controllable Vacuum Chamber at 1600 deg. C.

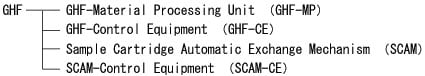

Outline of GHF

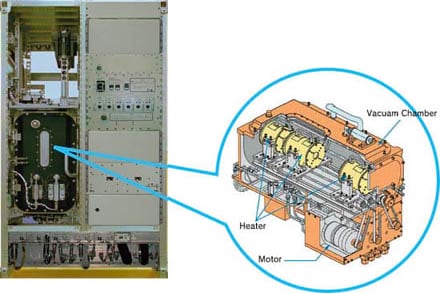

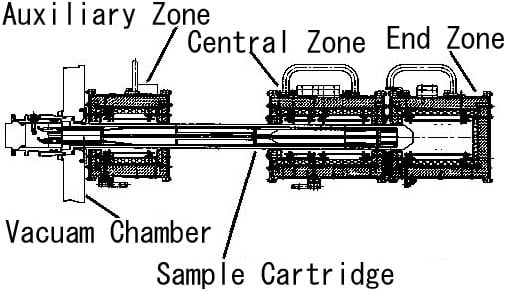

The Gradient Heating Furnace (GHF) is a vacuum furnace that contains three heating blocks. Their positions and temperatures can be independently controlled, and various temperature profiles can be realized. This facility will be mainly used for high quality crystal growth experiments using unidirectional solidification. GHF has an automatic sample exchange system that can be accommodate up to 15 samples to reduce crew operation.

Heating Profile

The three independent heating zone can realize various temperature profiles to meet with variety of experiments from researchers

Independent Heating Zone

Various experiments can be realized with high temperature (Max.1600 deg. C) and highly stable temperature accuracy.

- Central Zone : 500 to 1600 deg. C

- End Zone : 500 to 1600 deg. C

- Auxiliary Zone:500 to 1150 deg. C

- Temperature Stability : ±0.2 deg. C

Drive mechanism of heating zone

High accuracy of speed control (better than ±0.1 %) at 0.1 to 200 mm/hr.

Install samples

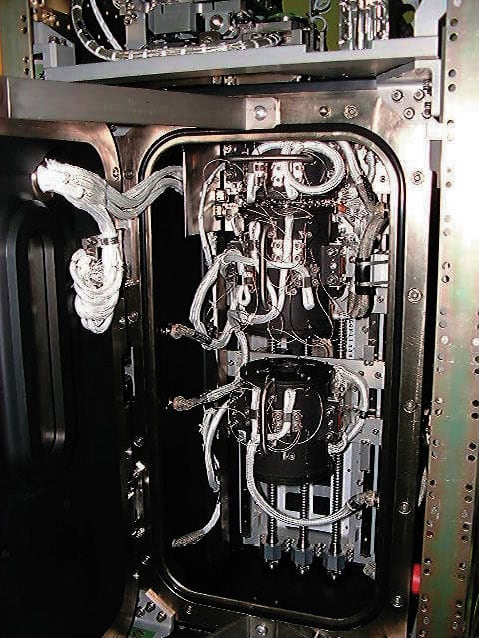

Sample Cartridge Automatic Exchange Mechanism (SCAM)

Experiments can be performed automatically by installing 15 sample cartridges (Max.) in SCAM

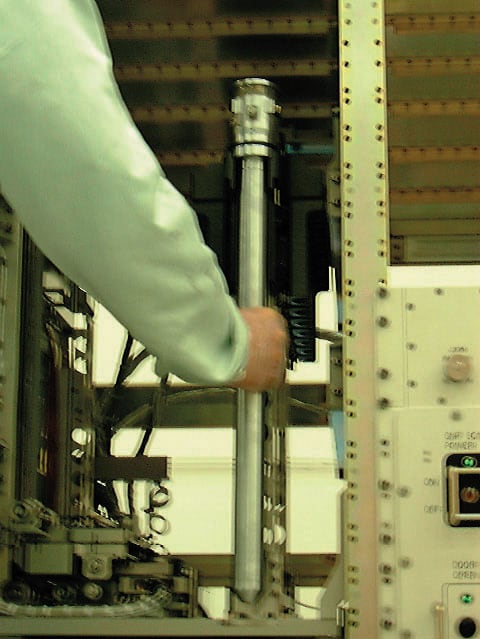

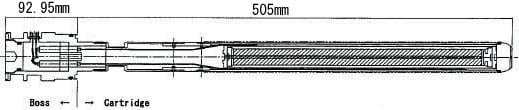

Sample Cartridge

A sample from a researcher is contained in a sample cartridge. The standard sample cartridge is shown below. The standard cartridge has five thermocouples that can be freely positioned by the researchers.

Moreover, researchers can make custom sample cartridges to suit own experiment requirements.

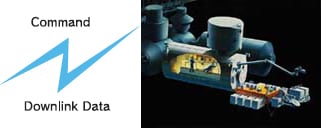

Operation

Interactive Experiment with Commanding from Ground Operation Center

GHF is operated automatically in accordance with the temperature profile of each heaters. The researchers can confirm the progress of their experiment with downlinked temperature data. Moreover, they can change temperature settings of each heaters during the experiment by sending commands from the ground.

Specification

Major Components

| Item | Specifications | |

| GHF Characteristics | Heating Temperature Range | End Heater : 500 to 1600 deg. C (Moving distance : Max. 200 mm) Central Heater : 500 to 1600 deg. C (Moving distance : Max. 250 mm) Auxiliary Heater : 500 to 1150 deg. C (Moving distance : Max. 250 mm) |

| Temperature Stability | ±0.2 deg. C or better | |

| Temperature Accuracy | ±0.4 % or better | |

| Temperature Gradient | Up to 150 deg. C/cm (@1450 deg. C) | |

| Speed | 0.1 to 200 mm/hr or 600 mm/hr | |

| Speed Stability | ±1 or better (10 to 200 mm/Hr) ±10 or better (0.1 to 10 mm/Hr) |

|

| Insertion Slot Diameter | φ 40 mm | |

| Sample monitoring | Temp. : Up to 10 points * 2 ranges (Hi/Lo) 5 points (standard) * 2 ranges (Hi/Lo) Pressure : Diaphragm pressure sensor, Pirani gauge transducer, Cold cathode transducer |

|

| Marking Device | Pulse current interface is available (Marking). | |

| Continuous operating time | 300 Hours at maximum temperature | |

| Max. Power | Up to 5300W | |

| Cartridge | Dimension | Boss : 93 mm Cartridge : 505 mm (φ 34.4 to 36.1 mm) |

| Mass | Up to 6 kg | |

| Max. sample dimensions | φ 31 mm x 370 mmL (common sample cartridge) | |

| Temperature Monitoring | 5 points (Max.10 points) | |

Unless specified otherwise, rights to all images belong to ©JAXA